Source: Equipment World

This article originally appeared on EquipmentWorld.com – a leading media site serving up the latest news in construction, heavy equipment, pickups and everything else that helps you get the hard work done.

It is re-posted with permission

For several years, Jon Rosas had a front row seat in the equipment business, working in the rental division of Mustang Cat. It was there that he met contractor James Jayroe with Jayroe Construction. The two became fast friends.

“I asked him to let me work with him for free on weekends so that I could learn how to run the equipment,” Rosas says. “That way whenever a question came up with a customer maybe I could help them troubleshoot it.”

Eventually, Jayroe asked Rosas to join him as an estimator and provided lessons on estimating and plan reading. But the two couldn’t work out an agreement, so Rosas stayed put and the friendship continued.

A few years later, it was Rosas who asked Jayroe about a job. This time, though, Jayroe had a counter proposal: start your own business. “Here it is 24 years later, and I’m still doing what he taught me to do,” Rosas says with a grin.

Equipment WorldPatch Work

“We started out doing what they call patch work, which is basically work that nobody else wanted to do,” Rosas says. “I thought it was an opportunity other guys were missing out on.”

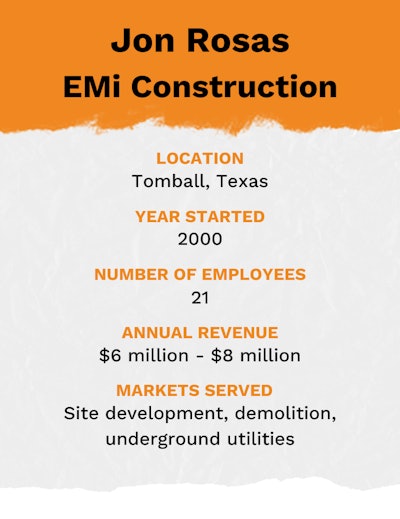

Today, EMi Construction, with annual revenues in the $6 million to $8 million range, focuses on land clearing, excavation and development work.

Located in Tomball, Texas, EMi works throughout the greater Houston area.

Top-Notch People

“Our people make us unique,” Rosas says. “Without them, EMi wouldn't be who they are today. I consider ourselves a player in the industry, and I owe it all to them.”

“These guys work so well together," he adds. "It's like they almost know what they're thinking or what their next move is going to be. They're a diverse group of guys. They're top-notch.”

To ensure this top-notch crew stays safe, EMi has a “tailgate party” every morning going over the work planned for that day and what might go wrong. “We need to make sure that we know what we’re looking out for,” Rosas says. This safety standard helps the company maintain its 0.84 experience modification rate.

Rosas appreciates the younger generation coming into the field. “It's the hungry ones that are striving to do better for themselves that you have a pleasure of helping because you want to see them succeed,” he says. “There's enough work for everybody, from the smaller guys to the bigger guys. It doesn't matter.”